Click to view our Accessibility Statement or contact us with accessibility-related questions

Showing 1 of 10 conversations about:

reswright

3850

Jul 28, 2020

bookmark_border

NICE work. Elegant and minimalist, showing good craftmanship. Way too expensive tho. With these prices you're gonna end up having QAnon people accusing you of smuggling children in wooden trays or something.

Stuff like this is for someone to advertise buying power. Not saying there's no place for that, but it's only something to do if you're made of money and want ppl to know that. Everyone else repurposes some other low cost item or upcycles something and IMO they end up with something cooler.

I think if y'all want to sell a bunch of these you want to prolly be at about half this price. YMMV tho

reswright

3850

Jul 29, 2020

bookmark_border

reswrightMaybe $40-45, thinking on it a bit more. The lip in the middle would be hard for a woodworker to do by hand, but if the wood's being milled it's as easy as skipping a couple passes. but it's either one hell of a machine, or someone's still finishing these up by hand one at a time, judging by the finish in the photos.

I like the material choice and the design ethos. But for sixty-five clams, you might as well call it the Nocturn Omission

Kavik

5531

Jul 29, 2020

bookmark_border

reswrightNocturne Omission just about killed me hahaha

Honestly, I've been mulling over the design while putzing around the house here, and I can't see any reason this whole thing can't be made with just 2 router bits, a jig, and some sanding.

Agreed that it does look like it might be hand sanded due to the shape, which does add SOME labor cost, but yeah......I'll sand anything you want at $40+/hr lol

reswright

3850

Jul 29, 2020

bookmark_border

Kavik 2 router bits, a jig, and some sanding.

Well, also a router. Or at least a Dremel and a router mount for it.

And clamps.

And some wood glue.

And a joiner machine to mill off the surfaces that are being glued and clamped together. Not cheap. I mean, it's spinning blades at thousands of RPMs, you wouldn't want it to be all that cheap. And it really isn't so at least that's good.

But if you had all that stuff then yeah, you'd just need two router bits, a jig you'd probably have to make yourself out of scrap anyway, and some abrasives.

Kavik

5531

Jul 29, 2020

bookmark_border

reswrightLol yes, i did assume a router, to go with the bits. (I don't think dremel sized shanks would be advisable for the size bits those contours would need)

I was really saying for anyone who has a basic hobbyist woodshop, and the skills to use their tools.

A jointer, i don't have. But people made perfect joints with hand planes for a long time before those were invented 😉

You can also do a really good job cheating it with a straight cut router bit. Doesn't even have to be straight then, you could make it a wavy joint as part of the design, if you wanted.....or if you got sloppy lol

P.S.

I also figure if you have hand planes and a router, chances are you already own clamps and glue 😅

reswright

3850

Jul 29, 2020

bookmark_border

KavikOf course you can use 19th century tooling, also known as 'the reason joiner planers exist and people are willing to pay for one', but I think you must concede that at that point there ain't no 'just' about the level of effort being put in, and if you aren't skilled already with it you're facing a learning curve the general size and shape of the Matterhorn.

On the other hand, a day spent working with those tools and you don't need a trip to the gym. Just some bandaids in varying sizes.

Kavik

5531

Jul 29, 2020

bookmark_border

reswrightI'll concede that it takes some effort to learn, but it's honestly not as hard as all that.

Getting 2 half inch boards planed square to glue up shouldn't take more than a couple minutes, once you're practiced at it, assuming you're using the right plane and are starting off with decent quality cut boards

Now... Restoring and working with ACTUAL 19th century tools? That's where the real fun begins, in my opinion 😁

(Edited)

reswright

3850

Jul 30, 2020

bookmark_border

RayFRay, I grew up around a wood shop.

Have your little episode if you’re gonna, but understand it’s obvious you’re picking a fight, it’s boring, and that nobody else cares if you get your ass in a knot over critical comments on low material costs vs high prices, which couldn’t be more of a photography cliche if it tried.

reswright

3850

Jul 30, 2020

bookmark_border

RayF

RayF

22219

Jul 30, 2020

bookmark_border

reswright

You seem to be evading the question.

I'm simply accusing you of being full of shit (and talking through your hat).

If you can counter that point with some examples of your router handiwork--especially anything that suggests you aren't full of shit, I'm willing to reconsider my position ;- )

reswright

3850

Jul 30, 2020

bookmark_border

RayFHow to get RayF’s goat:

1) Ask how much one of his photos costs to buy

2) When he quotes a price, Say ‘all that for five bucks worth of raw material? An outrage!’

what you do with his goat, stays in Vegas I guess

RayF

22219

Jul 30, 2020

bookmark_border

reswright

You're referring to my photos?

Well, I'm thrilled to hear you took the time to look them over! Actually, none of them are for sale, and at this point--they exist only as pixels on your screen. Not sure how to calculate the price of a pixel?

On the other hand, the cost of my equipment, and my immense talent--well, that's priceless ;- )

reswright

3850

Jul 30, 2020

bookmark_border

RayFI’d use a jig. Which I’d have to freehand assemble from leftover scrap stock. Hardest part, prolly.

I’d trace one square hole template with a box notch.then flip it over for the other side. This gives you the two depressions but the lip still goes from side to side.

The adjoining cuts connecting the two pockets could probably be made with a simple fence instead of a jig. That still would not be freehanding.

Flip it over, change the bit and do the bottom bevel.

Sand, stain, seal with a food grade polyurethane. It’s been over 20 years since I’ve been in a wood shop but I had fun in them when I was in there.

reswright

3850

Jul 30, 2020

bookmark_border

RayFAll that money won’t buy you back your goat. There’ll be another trip to the Goat Store in store for you, alas

Kavik

5531

Jul 30, 2020

bookmark_border

RayFIf i was making them on a CNC? In a large scale production, at a professional mill?

Less than this.

I usually find your poking at other people mostly humorous and often logical....but i really don't understand the coarse hair up your butt on this one?

You're going on about it as if this is some expertly hand crafted item made by some individual pouring his blood and sweat into it....when in reality, it's a mass produced item, most likely machine made and hand sanded, then shipped off to another company that just has to put their name on the packaging and sell it alongside the rest of their inexplicably overpriced items.

I wish we could actually know what the mystery mill is getting per unit, vs what Craighill is charging.

I wonder if your tune would change then?

Or does the cost balance then shift to marketing?

You can be offended on behalf of this "design company". I choose to be offended on behalf of the woodworkers who DO put all that effort into making hand made items and struggling to get fair prices for their work because the market is flooded with a mix of overpriced cnc work or underpriced imports.

reswright

3850

Jul 30, 2020

bookmark_border

Kavikhttps://www.etsy.com/listing/784456016/rectangle-reclaimed-wood-serving-tray

See, like this. Made outta upcycled shipping pallets.

14x6, so slightly bigger, but about the same space. Made in the US. Thirty bucks.

RayF

22219

Jul 30, 2020

bookmark_border

reswright

Might work but results from unit to unit would vary. No idea how long all that would take you.

I’m betting this guy uses a CNC that allows him too quickly crank out multiple units with very few variations and minimal tool changes.

In other words, you might be able to emulate the product but this guy is basically cloning a single perfect piece, in mere minutes per unit.

You might be able to build Ferrari in your basement too, but I doubt you’d be competitive with the factory version.

RayF

22219

Jul 30, 2020

bookmark_border

Kavik

Of course they are mass produced, that was my point. How much you’d sell yours for remains to be seen. The only offense I took was to your ignorance of the realities involved in producing an marketing the product.

By the way, I’m typing this comment on a phone I built all by myself in my garage with simple woodworking tools—for half the price of an iPhone!

(Edited)

Kavik

5531

Jul 30, 2020

bookmark_border

RayFFunny...your original point, in the other comment thread, was that walnut is SO expensive (per board foot).

Then your point was that it's not about the cost of materials, it's about the time/effort/skill put into it. Your Ferrari is worth more than the sum of its parts.

Now your point is that they're able to churn these out, en masse, with very little time or effort involved, and that somehow makes it worth more to you?

Your inconsistencies are showing...

I don't know what world you live in man, but the whole idea behind industrialisation and mass production is that it's meant to drive the cost of labor down, which in turn is supposed to be reflected in the final cost to consumers.

And, as if on cue, there's you bringing up the effort involved in bringing a product to market, when all other points are failing.

Time and time again, you love to challenge people when they voice their opinion on pricing of items, always with the "so where can we find yours for sale" type comments, followed by "you don't understand the business end of it".

Not sure why your default setting is to assume that people commenting on these things have zero practical knowledge of what they're saying.

Just because i haven't quit my career to spend my days in the shop and spend my evenings slinging my wares, doesn't mean I can't look at this and say my god, that's a lot of money to be asking for such a simple product

KestrelX

135

Jul 30, 2020

bookmark_border

reswrightYes and the other side will claim that polished Walnut spreads COVID-19 so we all have to wear masks and quarantine forever.

reswright

3850

Jul 30, 2020

bookmark_border

RayFI’m betting this guy uses a CNC that allows him too quickly crank out multiple units with very few variations and minimal tool changes.

Uh... no shit, Ray. Except 'this guy' doesn't use jack, he's a designer sitting in Brooklyn and these are made in Michigan. But aside from that, it's obvious. Of course they're CNCed. if you think this is your major insight that the rest of us don't understand, maybe finish sobering up before you decide whether you need to keep it up.

Not that you had a point to begin with. you were just triggered by someone questioning a high price, as seems to happen with you every few days. And now you're just moving your goalposts some more because you're getting dunked on, and going from 'hic, sheesh, you guys don't know woodworking, ha ha' to 'well you couldn't do as good a job as a CNC machine' as if one needs to be able to outperform one before one can notice that a piece of wood is overpriced. And the funny thing is, you don't apparently don't even know shit about woodworking yourself based on your answers.

You're way too easily stung by people noting that a professional is choosing a ripoff price for their product... and that's just you completing another cliche, Ray.

reswright

3850

Jul 30, 2020

bookmark_border

Kavik"Not sure why your default setting is to assume that people commenting on these things have zero practical knowledge of what they're saying. "

projection? :)

You're not supposed to notice when someone's ripping someone else off, I think it hits a little close to home for this guy

reswright

3850

Jul 30, 2020

bookmark_border

KavikAlways wild to see what people communicate, while they're trying to communicate some other thing

RayF

22219

Jul 30, 2020

bookmark_border

reswright

Too cheap too buy the product, and likely too dumb to program a CNC!

Guess you’re just gonna have to keep tossing your keys in that old kitty-litter box on your nightstand ?

Well take heart; someone here is bound to whip you up one any day now—for about five-bucks, and by hand ;- )

reswright

3850

Jul 30, 2020

bookmark_border

RayFWhat's that? You know deep down that your work isn't worth what you charge, and it makes you feel so wretchedly insecure to hear anyone talking about such a thing that you gotta have a little rant? ;-) That you can't help it? ;-) That it makes you feel bad about you? ;-)

Sorry, Ray, didn't quite catch that.

reswright

3850

Jul 30, 2020

bookmark_border

Kaviklol I don't think we were supposed to notice that he's upset

reswright

3850

Jul 30, 2020

bookmark_border

reswrightWhy are responses being hidden, folks?

I can post the screenshots if I need to, elsewhere if I need to.

Kavik

5531

Jul 30, 2020

bookmark_border

reswrightI think it's just drop being glitchy. When I clicked an alert for one of your posts earlier it said the post didn't exist, but then I saw it show up 10 minutes later

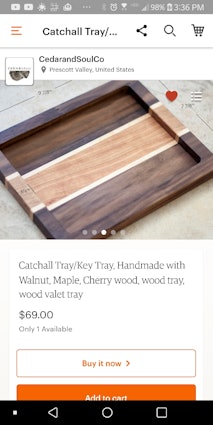

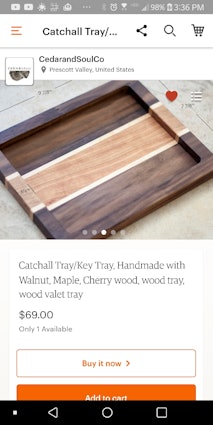

In other fun finds:

For right around the same price shipped, made in Arizona, 1 piece at a time

3 kinds of wood, 4 joints, 8 surfaces to prep for joining, before routing and sanding and finishing... That sounds like a much more reasonable materials/labor/cost ratio to me 👍

https://www.etsy.com/listing/824031710/catchall-traykey-tray-handmade-with

reswright

3850

Jul 30, 2020

bookmark_border

KavikThat one's nice, too. A little highly stylized but it looks visually interesting.

Don't get me wrong, I'd love to learn hakone and be the guy who uses hand tools to make woodwork with intricate marquetry and hand planes his wood so flawlessly that something like this would stick together in the long term. I think that'd be about as satisfying a way to spend old man days on the porch as it gets, and god knows it's beautiful work.

Absent Jedi levels of skill and patience when it comes to woodworking, though, you'd totally want a machine jointer if you wanted to make things like this, and not have them be prone to come apart at the seams in five years.

Kavik

5531

Jul 30, 2020

bookmark_border

reswrightSorry, but this makes no sense to me.

There's absolutely no reason that a joint made with a hand plane would have any higher rate of failure down the road than one made on a jointer.

A flat surface is a flat surface. If your surfaces weren't flat, parallel to eachother, and perpendicular to the sides, you would know that before even applying the glue.

Planing a surface that's narrower than your plane blade isn't black magic, it's about as simple a task as you can ask for, in regards to planing.

If you're really that worried about it, then don't use a butt joint. Make it a lap joint, double your gluable surface area, and have the glue holding from 2 directions.

Or keep it a butt joint and use biscuits or pegs.

Or go nuts and cut finger joints, or rabbets, or line the seam with bowtie inlays.

There's dozens of ways to join 2 boards, what you see here is the bare minimum simplest method (unless there are hidden pegs/biscuits, then it's one step up from that)

If you make it yourself, you can overbuild it to your heart's content 😉

reswright

3850

Jul 30, 2020

bookmark_border

KavikThere's always some variation when you use hand tools though. Yes, the blade on your hand planer can be wider than the board face - but that blade also flexes minutely as it's pushed along the face. Wood itself has uneven grain offering differing resistance as you plan. Looks fine to the eye, but it's less regular than what you get slowly moving the face of the wood over the rotating blades of a jointer planer and the little differences add up to a seam that's easier to split or delaminate.

I might be overblowing it a little but this is both from what I remember, and from what a guy told me who makes his own butcher blocks out of end grain cut wood, when I asked him about using hand tools. The more pieces of wood you're laminating together, the more important it is that the seams be seamless.

Don't get me wrong, how a man makes his own sawdust is his own business, and I like the idea of people bringing back the old skills and folks having marquetry on their sideboards and gingerbread on their eaves again, but it's like this. You might try 19th centurying it if you had to make one, for you, which if it broke you'd just reglue and clamp again, but if you had to make 10 or 20 for people who would be pissed if you made one for them and it came apart at that seam... you'd be wanting that machine.

(Edited)

Kavik

5531

Jul 30, 2020

bookmark_border

reswrightI get your point, in theory, but wood itself moves a lot more than a plane blade flexes on wispy thin cuts.

Most wood I've seen split from joints like this are due to drastic humidity changes in the atmosphere, or something spilling on it where the finish was worn, causing warpage as the piece dries unevenly.

Machined or hand planed, there's still a layer of glue between the two pieces that should make up for any discrepancy that's too minute to see with the naked eye.

Think about how much furniture still exists in the world that is hundreds of years old and still in one piece. Things that see more abuse than this ever should. Though, admittedly, not as much as a cutting board.

It's impressive that the guy goes through that much trouble to use a jointer, but LOTS of people do endgrain cutting boards that hold up with just table saw cuts on 2 faces, and thickness planed (by machine) faces on the other 2.

I think we're also getting things muddled with the differences between jointing and planing, but that's a whole other topic

reswright

3850

Jul 30, 2020

bookmark_border

KavikThink about how much furniture still exists in the world that is hundreds of years old and still in one piece

Right. Now think about how often you come across a two hundred year old armoire. Let alone, you know, like a five hundred year old one.

Actually somewhat rare, right?

Now think about how many more still would exist if they'd had better tools when they made 'em :P We'd be like 'dude, what, you didn't inherit an armoire the normal way? WTF did you buy one for?'

reswright

3850

Jul 30, 2020

bookmark_border

reswrightI mean, don't get me wrong. My dad would tell you his woodwork projects ended up being more glue and putty than wood, by weight, when done.

And I know that's common. I've watched many an hour of the Yankee Workshop, to the point that I expect Norm Abram could probably find a way to make a glass chandelier with biscuits and glue. Bustin' out the dado, you know it's Norm.

lol, it's more like 'you do it your way, I'll do it my way, and I bet I end up swearing less than you'

Kavik

5531

Jul 30, 2020

bookmark_border

reswrightLol Sure, they're SOMEWHAT rare. But we live in a throw away society, and have for a long time now.

And I think I could say I've seen more that are just beat to hell and chewed up, rather than having their panels splitting. (short of any sighs of obvious water damage)

But based on the number of pieces out there that are still holding up, I think that has more to do with us as negligent people than them as faulty craftsmen with substandard tools 😝

Kavik

5531

Jul 30, 2020

bookmark_border

reswrightLol a chandelier made of long strings of glue, with dangling biscuits... Now that's a funny thought haha

Don't get me wrong, i have plenty of power tools, I'm not saying I would do everything by hand, just saying that there are alternatives that still work just as well as they did, for those who don't have 10 grand invested in their workshop, ot don't have the space for all the big tools.

My "shop" at the moment is an enclosed porch that measures 14' 4" x 7' 8".

In that area I have permanent places for a work bench, band saw, drill press, lathe, standing tool chest, and 2 shelf units, plus a peg board on one wall. Everything else (contractor's table saw, thickness planer, mitre saw, scroll saw, belt sander, spindle sander, grinders, etc, etc) all live on the shelves and only get taken out when needed.

Sure as shit there's no room to set up a big floor standing jointer out there lol

And from what I understand, the smaller benchtop ones are barely worth owning.

I got no problem with "your way" if you have the money and the space, and yeah, you might swear less often....but I bet you'd swear louder if you run your thumb over a jointer blade then I would of i nick myself on a hand plane lol

Kavik

5531

Aug 10, 2020

bookmark_border

RayFLol okay, i know this drop and this conversation were both long since over and done with...but i just stumbled across this gem, and had to share it here lol

Also @reswright

https://store.wallpaper.com/en/workspace/ac12-pen-tray-brown-E15E15AC1469BRW.html?cgid=workspace#page=1&start=10

Makes this little tray look like an absolute bargain!! 🤣🤣