Click to view our Accessibility Statement or contact us with accessibility-related questions

Showing 1 of 1309 conversations about:

Pilgrim

8

Jul 7, 2015

bookmark_border

chilofthehorn

213

Jul 7, 2015

bookmark_border

PilgrimHAHHA - just get some ones from WASD, the stock ones suck bro.

Pilgrim

8

Jul 7, 2015

bookmark_border

chilofthehornI've actually done just that and bought some cherry stabs for good measure from mouser.

I was initially concerned that the plate might have been cut using improper measurements/spacing but I think at the very least cherry stabs will solve that if needed.

I was initially concerned that the plate might have been cut using improper measurements/spacing but I think at the very least cherry stabs will solve that if needed.

flipjsio

101

Jul 7, 2015

bookmark_border

PilgrimIts the same with the normal plate. I think the hole for stabs a bit small making the opening smaller, resulting to key get stuck on way up. Or it could be the stabs is the problem. Had email correspondence with Massdrop Support, but so far no resolutions. Haven't received anything yet from them except for the correct spacebar keycap that they initially sent the wrong one.

Pilgrim

8

Jul 8, 2015

bookmark_border

flipjsioGlad I'm not the only one. I also go the wrong spacebar too so I'm waiting for that to be resolved.

If I can find a spec sheet I was thinking of getting my caliper and comparing measurements.

I also think the positioning of the holes is too close to the switch and possible prevents the metal bar from being fully grabbed by the clips, compared to my WASD keyboard the metal bars almost fall out as they bump up against he bottom of my switch.

If I can find a spec sheet I was thinking of getting my caliper and comparing measurements.

I also think the positioning of the holes is too close to the switch and possible prevents the metal bar from being fully grabbed by the clips, compared to my WASD keyboard the metal bars almost fall out as they bump up against he bottom of my switch.

Kaan

297

Jul 10, 2015

bookmark_border

PilgrimI also noticed this and reported it here

The wires they sent are just low quality wires that will never work, I can't believe no one noticed and reported this before, they are probably going to assemble KC60's with these wires too, as I see from the first review photos

On the bright side, WASD keyboards saves the day with their decent, high quality and cheap stabiliser parts

The wires they sent are just low quality wires that will never work, I can't believe no one noticed and reported this before, they are probably going to assemble KC60's with these wires too, as I see from the first review photos

On the bright side, WASD keyboards saves the day with their decent, high quality and cheap stabiliser parts

Pilgrim

8

Jul 12, 2015

bookmark_border

KaanYup your right, just finished building it.

My first keyboard was a CODE 104 so I know from experience I can rely on WASD for good quality replacement parts and thusI immediately ordered new stabs and wires.

Upon closer inspection it became obvious that the gauge of wire used in the kit was much thinner than the WASD wires and the stabs didn't grab it as tightly when it clicks in place.

My caliper shows the WASD wires to be 1.18mm vs the 0.98mm on the stock wires supplied for the fist drop of the infinity. Maybe this was done to save on volume costs but instead it adversely affected my build experience.

EDIT: The wire for the space bar was the same thickness as the WASD but I still replaced it as it felt kinda flimsy by comparison.

I'm not sure if the plastic stabs were also inferior quality but they were so worn from my testing/removing them that I just used the replacements instead.

Also worth noting the solder points for the USB connector were very shallow and I reinforced those with extra solder since it's a potential stress point for the cable.

I was really annoyed with this build as it shouldn't have been an issue but at least MD support is attentive and great at receiving feedback so I'm sure this will be fixed in the next round of drops.

My first keyboard was a CODE 104 so I know from experience I can rely on WASD for good quality replacement parts and thusI immediately ordered new stabs and wires.

Upon closer inspection it became obvious that the gauge of wire used in the kit was much thinner than the WASD wires and the stabs didn't grab it as tightly when it clicks in place.

My caliper shows the WASD wires to be 1.18mm vs the 0.98mm on the stock wires supplied for the fist drop of the infinity. Maybe this was done to save on volume costs but instead it adversely affected my build experience.

EDIT: The wire for the space bar was the same thickness as the WASD but I still replaced it as it felt kinda flimsy by comparison.

I'm not sure if the plastic stabs were also inferior quality but they were so worn from my testing/removing them that I just used the replacements instead.

Also worth noting the solder points for the USB connector were very shallow and I reinforced those with extra solder since it's a potential stress point for the cable.

I was really annoyed with this build as it shouldn't have been an issue but at least MD support is attentive and great at receiving feedback so I'm sure this will be fixed in the next round of drops.

chilofthehorn

213

Jul 12, 2015

bookmark_border

PilgrimThe USB connectors it came with are JUNK. I ended up having to replace mine as the INSIDE of the USB connection port became squirrly after just a couple of weeks.

Replaced it with the exact same style of Molex made connector.

BTW guys I have managed to revive using a freescle programmer temporarily on Linux machines only for the time being.

Yeah, I have a board design going for a unique 60%+numpad with no function keys. Luckily for me, cases and plates are a non issue for me to CNC as I have access to a Haas Mill, lasef, routing table, and CNC plasma cutter. I will have to do some early testibg using 3d printing and Acrylic for the plate.

Replaced it with the exact same style of Molex made connector.

BTW guys I have managed to revive using a freescle programmer temporarily on Linux machines only for the time being.

Yeah, I have a board design going for a unique 60%+numpad with no function keys. Luckily for me, cases and plates are a non issue for me to CNC as I have access to a Haas Mill, lasef, routing table, and CNC plasma cutter. I will have to do some early testibg using 3d printing and Acrylic for the plate.

Kaan

297

Jul 12, 2015

bookmark_border

chilofthehornPilgrim, I don't think they are going to make improvements in these areas, indeed the support is good, yet they seem to only handle the aftermath and not make pre-emptive improvements to prevent issues, so I think the next drop of infinity's, maybe ergodoxers, and probably KC60'ers going to experience a portion of the problems we experienced - I gave up on contacting the support myself, otherwise I'm entitled to receive a pack of blues and 3 spacebars and probably stabiliser parts for 4 keyboards, yet it's simpler to spend ~$50 and buy them manually If I need to - even though they send replacements, after a point it becomes very tiresome to request replacements for every single thing

I'm very interested in your USB improvement chilofhtehorn, indeed the USB at least needs some additional solder, with my first build, I tied the usb connector, oversoldered it, and gorilla-glued it - with my latest build, I only oversoldered it and added some hot-glue for some basic absorptions

I was initially intending to drill the PCB to tie the usb connector, but skipped it on my latest build, the existing design fails if the USB is pushed down, tie-ing would prevent that scenario, but I didn't want to risk things - a pinned/soldered USB would prevent all these issues and last a life time

I'm probably going to attempt something like this next: http://www.keyboard-layout-editor.com/#/layouts/731936cc7250df5d3a2397768015ec17 I'm constantly being challenged by keycap availability, it never occurred to me that I could build custom layouts for the keycaps that I have, I'm probably going to build the above layout when the Retro SA set is launched (Layouts like these are also possible: http://www.keyboard-layout-editor.com/#/layouts/34f7ca4a8f5eceeefe918ba056bcf5a2 - worst case scenario, it would only require some drilled/removed paths to be manually re-wired, it would probably take 20 minutes versus hours/days/weeks/months spent on hunting the right keycaps)

The firmware still doesn't have features for mixing and overriding modifiers behaviours, so simplified layouts like the ones I linked above would be challenging to use, I really wish such features are added soon (For example, converting the Shift+Esc to a pure ~ is still not possible)

I'm very interested in your USB improvement chilofhtehorn, indeed the USB at least needs some additional solder, with my first build, I tied the usb connector, oversoldered it, and gorilla-glued it - with my latest build, I only oversoldered it and added some hot-glue for some basic absorptions

I was initially intending to drill the PCB to tie the usb connector, but skipped it on my latest build, the existing design fails if the USB is pushed down, tie-ing would prevent that scenario, but I didn't want to risk things - a pinned/soldered USB would prevent all these issues and last a life time

I'm probably going to attempt something like this next: http://www.keyboard-layout-editor.com/#/layouts/731936cc7250df5d3a2397768015ec17 I'm constantly being challenged by keycap availability, it never occurred to me that I could build custom layouts for the keycaps that I have, I'm probably going to build the above layout when the Retro SA set is launched (Layouts like these are also possible: http://www.keyboard-layout-editor.com/#/layouts/34f7ca4a8f5eceeefe918ba056bcf5a2 - worst case scenario, it would only require some drilled/removed paths to be manually re-wired, it would probably take 20 minutes versus hours/days/weeks/months spent on hunting the right keycaps)

The firmware still doesn't have features for mixing and overriding modifiers behaviours, so simplified layouts like the ones I linked above would be challenging to use, I really wish such features are added soon (For example, converting the Shift+Esc to a pure ~ is still not possible)

Pilgrim

8

Jul 12, 2015

bookmark_border

chilofthehornAre you saying you have had trouble with the freescale chip on this infinity keyboard?

chilofthehorn

213

Jul 14, 2015

bookmark_border

PilgrimSo, the freescale chip ended up being recoverable this weekend. I have programmers for those from having a pile of those Freescale Freedom boards around and they are locally here in DFW (I serve as a mentor at hackathons, both SW `and HW ones, and those guys have been at a few of the events). Plus, just happened to have the exact right size of chip clip as well from some Atmel project.

The advice I got from those guys was basically... reset the chip and reload. I used their command tools to do just that and it partially came back, working fully in Linux.

So, then started checking the caps:

C4 and C6 had to be replaced as well as the components used were reading wayyyyy off the schematic and floating in value beyond a 10-20% typical limit. Turns out that the C6 is the reset pin and flux is no beuno.

Added a 47uf smoothing cap at the USB connection and connected the USB shield to the plate for some extra RF happiness. I had already previously replaced the USB connector with a Molex one of the same exact type.

Then, it worked with Windows and Mac.

I am guessing that the chip got a surge from the Macbook it was connected to and that affected the Freescale chip, requiring a reset.

The advice I got from those guys was basically... reset the chip and reload. I used their command tools to do just that and it partially came back, working fully in Linux.

So, then started checking the caps:

C4 and C6 had to be replaced as well as the components used were reading wayyyyy off the schematic and floating in value beyond a 10-20% typical limit. Turns out that the C6 is the reset pin and flux is no beuno.

Added a 47uf smoothing cap at the USB connection and connected the USB shield to the plate for some extra RF happiness. I had already previously replaced the USB connector with a Molex one of the same exact type.

Then, it worked with Windows and Mac.

I am guessing that the chip got a surge from the Macbook it was connected to and that affected the Freescale chip, requiring a reset.

Kaan

297

Jul 15, 2015

bookmark_border

chilofthehornPlease start an infinity_keyboard_first_aid_kit GB, with a pack of spare/improved components :)

Honestly I'm very concerned, I was planning on using these PCB's for years

My electronical knowledge has perished over time, however, inspecting the PCB initially, I wasn't concerned too much (I was initially concerned just a little bit actually, as I was expecting more components), as there are extremely few components, I assumed the design and component selections were mainstream, widely used

Yet I'm guessing that's not the case and there is reason to worry

I would like to learn/see more, a guide, technical explanations, photos, blog post / forum post - would be awesome (for example, did you connect the USB housing that is soldered onto the PCB to the plate // why?)

Honestly I'm very concerned, I was planning on using these PCB's for years

My electronical knowledge has perished over time, however, inspecting the PCB initially, I wasn't concerned too much (I was initially concerned just a little bit actually, as I was expecting more components), as there are extremely few components, I assumed the design and component selections were mainstream, widely used

Yet I'm guessing that's not the case and there is reason to worry

I would like to learn/see more, a guide, technical explanations, photos, blog post / forum post - would be awesome (for example, did you connect the USB housing that is soldered onto the PCB to the plate // why?)

jabbajac

18

Jul 16, 2015

bookmark_border

KaanSeconded. It would be great to debug some of the issues that I'm having with this board.

chilofthehorn

213

Jul 16, 2015

bookmark_border

KaanSome of the biggest issues were clearly with the manufacturing and parts procurement which far outweighs any of the basic design issues IMO. Massdrop obviously knows VERY little about how to manufacture and part selection and dealing with Chinese part vendors or even authenticating those parts. Its something that I do all the time and even had parts custom manufactured in china to specifications without issue.

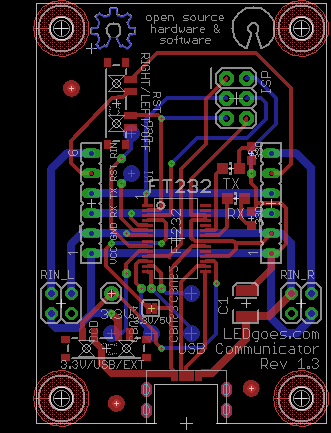

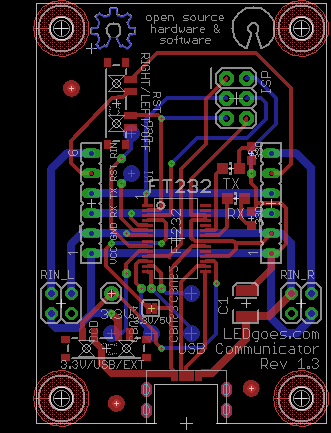

There are ways to make the PCB allow for those components to be added at the user discretion. I am one of the owners of a company that does small and medium run manufacturing and does open source hardware/software designs as well. We always design in ways that the user can add features or change out parts for different ones or add more if they want to.

You can count on me making a fork of the basic PCB and pushing up any changes and whatnot KiiiboHD and their github, so that they can take up what they would like at their choice. I'll just make something way over engineered and they can scale it back for most folks.

I will put together a little list and need to still show off my RGB backlighting solution.

I will make a little BOM and some instructions on my site for those who want to go to the extreme.

There are ways to make the PCB allow for those components to be added at the user discretion. I am one of the owners of a company that does small and medium run manufacturing and does open source hardware/software designs as well. We always design in ways that the user can add features or change out parts for different ones or add more if they want to.

You can count on me making a fork of the basic PCB and pushing up any changes and whatnot KiiiboHD and their github, so that they can take up what they would like at their choice. I'll just make something way over engineered and they can scale it back for most folks.

I will put together a little list and need to still show off my RGB backlighting solution.

I will make a little BOM and some instructions on my site for those who want to go to the extreme.

Pilgrim

8

Jul 16, 2015

bookmark_border

chilofthehornI may need to reset and reload the chip too then. In my testing of the board, pressing multiple keys felt choppy and a bit sporadic.

Pilgrim

8

Jul 16, 2015

bookmark_border

KaanYeah I'm pretty annoyed at these issues.

I hope the ergodox infinity doesn't suffer as a result from this too. I've actually contemplated canceling my order since the experience with this kit required me to order extra parts and troubleshoot things I shouldn't have had to.

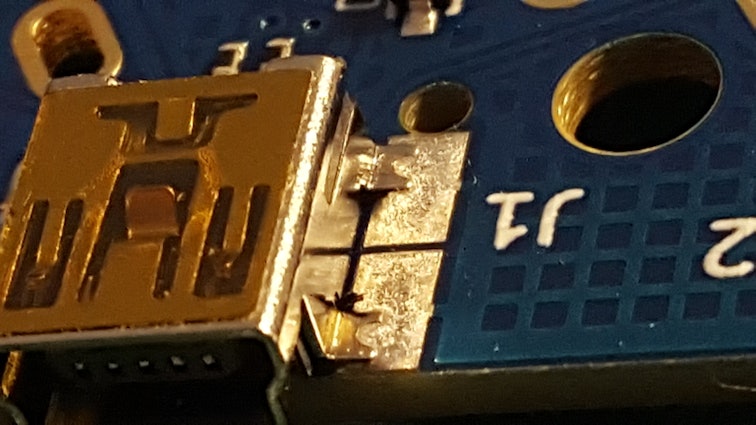

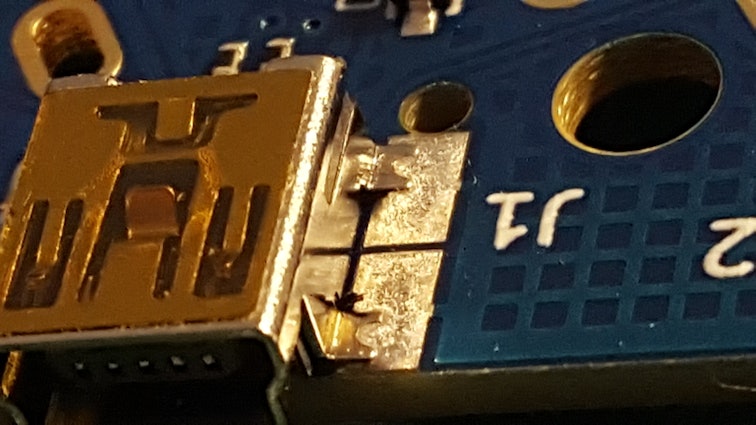

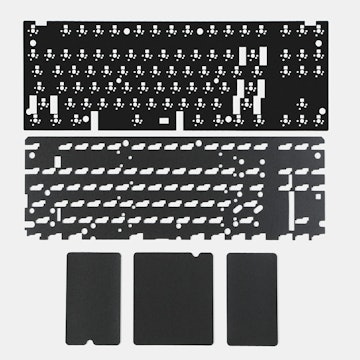

For the USB connector I added extra solder, pics below of that and the size diff in the stabilizers.

[img:IMG_20150711_201133.szb.jpg]

For the USB connector I added extra solder, pics below of that and the size diff in the stabilizers.

[img:IMG_20150711_201133.szb.jpg]

Kaan

297

Jul 18, 2015

bookmark_border

chilofthehornHey chilofthehorn,

Do you think these issues are severe enough to abandon the PCB's?

At this point, I'm only going to use the PCB's of the infinity, I'm considering getting Nerd 60 v2's instead, if you think the issues are severe (I have 3 endgame keyboards planned, have 3 infinity PCB's left to build them on, I would like to have a PCB that will last a lifetime)

Usage of such tiny SMD's is also pretty concerning, reduces the repairability to 0 -- with no led worries, such extreme amount of spaces, it would have been great if they used larger and potentially sturdier(?) components

Usage-wise speaking, I'm not even using the latest firmware that has some major improvements in terms of activation/debounce logic, however both Rev1.01b's I've used had no usage issues so far

I might just wait another month and get a winkeyless.kr or gon pcb if there is need to worry

Do you think these issues are severe enough to abandon the PCB's?

At this point, I'm only going to use the PCB's of the infinity, I'm considering getting Nerd 60 v2's instead, if you think the issues are severe (I have 3 endgame keyboards planned, have 3 infinity PCB's left to build them on, I would like to have a PCB that will last a lifetime)

Usage of such tiny SMD's is also pretty concerning, reduces the repairability to 0 -- with no led worries, such extreme amount of spaces, it would have been great if they used larger and potentially sturdier(?) components

Usage-wise speaking, I'm not even using the latest firmware that has some major improvements in terms of activation/debounce logic, however both Rev1.01b's I've used had no usage issues so far

I might just wait another month and get a winkeyless.kr or gon pcb if there is need to worry

chilofthehorn

213

Jul 20, 2015

bookmark_border

KaanThe PCB should be just fine. I would suggest adding in the smoothing cap (you can find a barrel style cap at RadioShack. I would also reinforce the miniUSB with some Sugru or Polymorph plastic. The board wasn't designed to use the PTH secured connectors and has no other reinforcement. You should prolly replace C4 and C6 though based on what mine was doing. This is just whomever did parts procurement getting the cheapest parts possible. The heat curve on the ovens used to make the boards is in line with a sub-$1000 solder oven operated by an idiot or they used really old solder paste that wasn't reconstituted. So just retouch the solder points on the board and use a little flux.

For an example of a reinforced connector here is an FTDI board I designed:

For an example of a reinforced connector here is an FTDI board I designed:

For some reason the stabilizer doesn't grab the metal bar as firmly as on my other keyboards and the stabs in the key make contact with the plate mount braces, as a result the key does not fully return on actuation.