Click to view our Accessibility Statement or contact us with accessibility-related questions

Showing 1 of 675 conversations about:

Drop + Dan Durston X-Mid 1P Tent

Bhsummer

1

Dec 7, 2018

Dan, specs are great. I have a question on the grommets do they have a backside so the tip of the pole isn’t rubbing directly on the re-enforced cone?

dandurston

5116

Dan Durston

Dec 8, 2018

BhsummerHi Bhsummer,

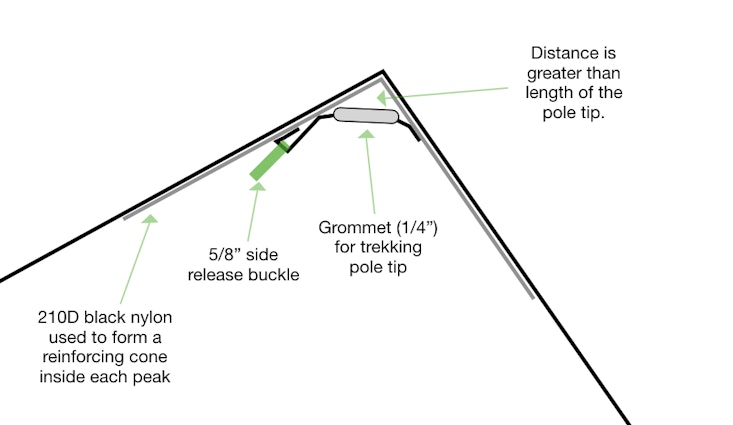

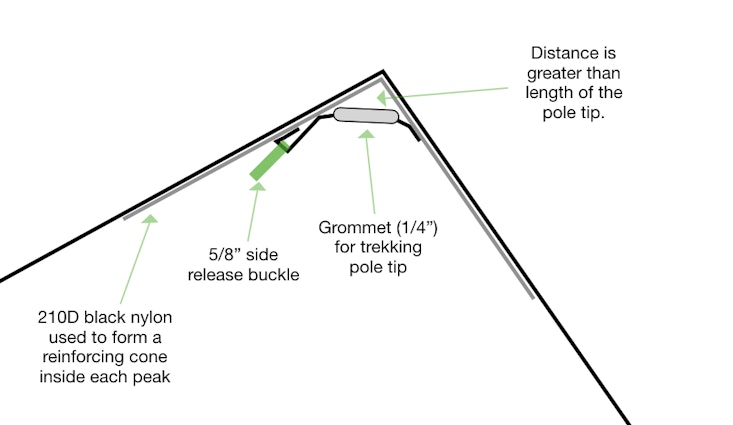

The short answer is no. The longer answer is that grommet area is carefully designed so that a potentially sharp pole tip isn't going to wear or cut through the 210D nylon reinforced cone. This is obviously super important so I've paid close attention to it. This is a hard to explain but I'll give it a shot.

Pole tips can be sharp and thus can potentially cut through almost any material if there is pressure on that material from the tip. So what is really important is designing the peaks in such a way that the load is transferred elsewhere and the tip isn't exerting pressure onto anything. If there was a backing and the tip put pressure on it, it would likely cut through eventually. There are double layers of webbing at the peaks and I considered just having the grommet through the lower one and having the upper as a backing, but it would have pushed on this and potentially worn through, so it seemed better to design a stronger grommet placed through two layers that is located a safe distance below the true peak so it won't push on that. Thus the grommet is sewn in, in such a way that the grommet is tensioned and the load is transferred to the pole around the tip, long before the tip pushes on the 210D nylon.

So in other words, the distance between the grommet and the true peak is much greater than the length of the protruding tip (see diagram below). The grommet itself is quite thick since it is a robust grommet and placed through two layers of webbing, so the pole tip hardly emerges at all from the top, and can not emerge far enough to put pressure directly on the 210D nylon.

(Edited)

Bhsummer

1

Dec 8, 2018

dandurstonThank you for the explanation I’ll be joining the drop. My first.