Spyderco Watu CPM20V Compression Lock Knife

A Tradition of Getting Things Done

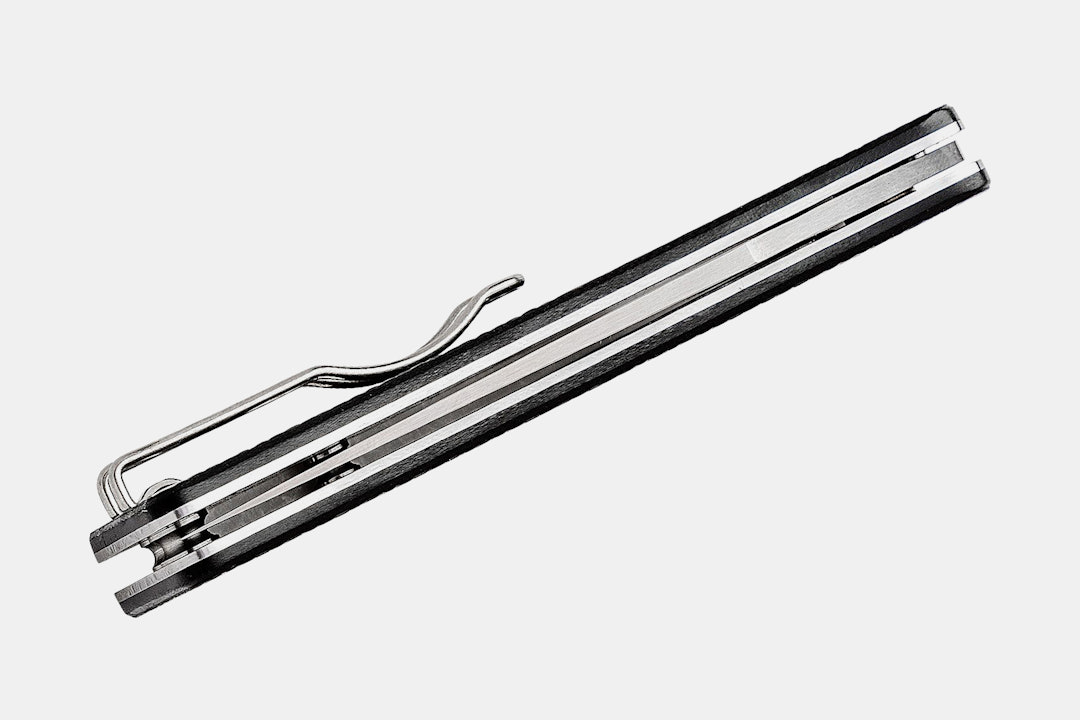

Inspired by the traditional knife of the Chokwe people of Africa, the Spyderco Watu is simple by design, but ready for complex tasks. The blade is technically a clip-point, albeit about the most barebones version you could draw up. Despite its scaled-back design, it’s excellent for control when slicing, piercing, pushing, and pulling. Plus, because of its CPM20CV stainless steel construction, it's built for the rigors of the outdoors. Shaped like an hourglass, the handle is made of a combination of carbon fiber and G-10 that shines in the light—perfectly complementing the satin-finished blade. Weighing just 3 ounces, the Watu carries on either side via the tip-up wire clip.

Note: Due to the sensitive nature of shipping knives internationally, we can only ship this knife to select countries. It is the responsibility of the buyer to know and comply with all importation regulations and local laws. Click here for additional information.

Specs

- Spyderco

- Blade: CPM-20CV stainless steel

- Blade type: Clip-point

- Grind: Full-flat

- Blade finish: Satin

- Handle: Carbon fiber/G-10 laminate

- Lock: Compression Lock

- Pocket clip for tip-up carry on either side

- Blade thickness: 0.1 in (2.5 mm)

- Blade length: 3.3 in (8.4 cm)

- Cutting edge: 2.9 in (7.4 cm)

- Closed length: 4.2 in (10.7 cm)

- Overall length: 7.35 in (18.7 cm)

- Weight: 3 oz (85 g)

Shipping

Estimated ship date is Jan 11, 2021 PT.

Payment will be collected at checkout. After this product run ends, orders will be submitted to the vendor up front, making all orders final.