Click to view our Accessibility Statement or contact us with accessibility-related questions

American Knives in 2019

Seeing as Drop has recently relisted a couple of their collaborations with US production knife makers like Millit and Pro-Tech, made in the US, let's talk about American knives! Post some pics of the ones we own and like and why, especially firms you wouldn't mind seeing Drop work with if they get a chance and the stars are right.

I'll go first with a pic - here’s a representative sample of the US made production knives I own.

(Edited)

search

close

Sort by: Newest

keyboard_arrow_down

reswright

3850

Aug 22, 2020

American Made Knife Steel Pricing

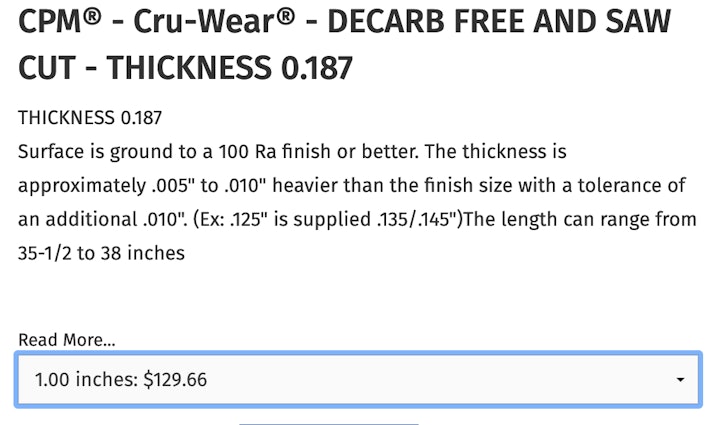

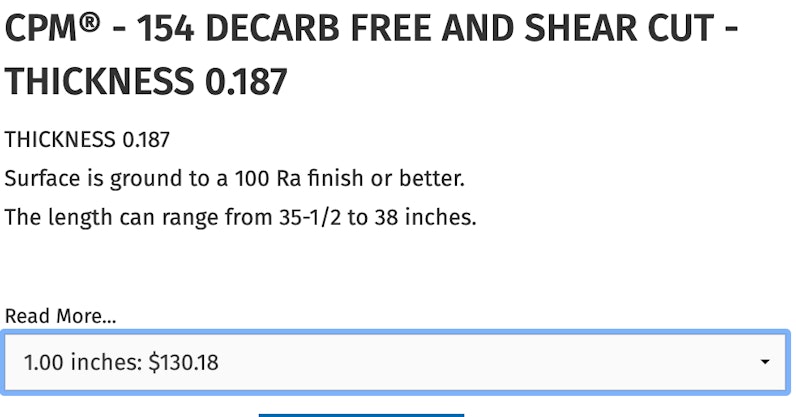

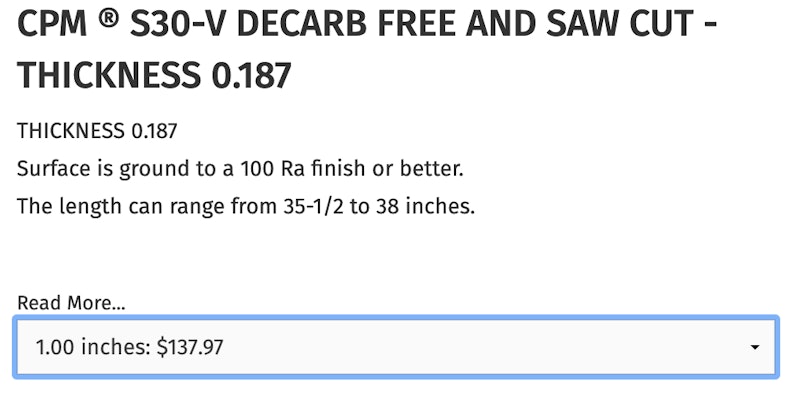

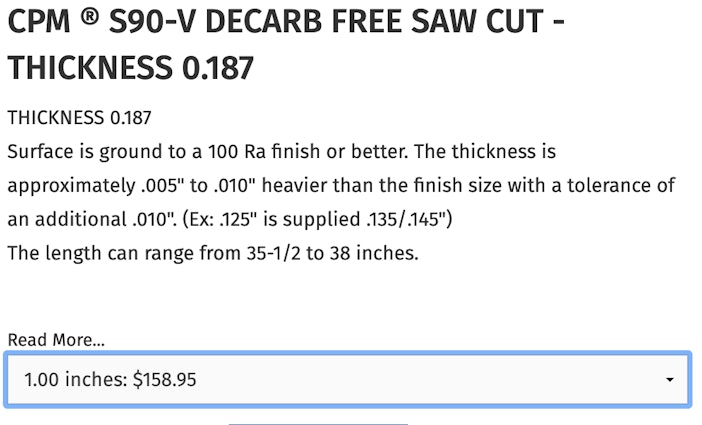

I took a trawl through the Niagara Specialty Metals pricing website to look at what true wholesale costs for the knife steels they produce. NSM is one of the American mills that makes Crucible's steel; companies like WE Knife buy steel directly from them, so NSM's wholesale price for common knife steel gives you a rough comparative idea of how much one grade of knife steel will cost them as opposed to another. Always interesting when comparing models of knife, grades of steel and prices.

So here are the prices I snapped for equal sized billets of different knife steels at the same grade of prep (that is to say, with thickness .187 in, width 1 in, and lengths roughly equal to 1 yard, cut from a beam with a saw and with a smooth ground surface. )

(Ingot) 440C: $92.74

(Ingot) D2 $101.13

(Ingot) 154CM $116.14

(PM) CPM-D2 $122.44

(PM) CPM-154 $130.18

(PM) CPM-S30V $137.97

(PM) CPM-S35VN $137.61

(PM) CPM-S45VN $136.56

(PM) CPM-S90V $158.95

(PM) CPM-20CV $164.96

(PM) CPM-CruWear $129.66

(PM) CPM-M4 $133.74

(PM) CPM-3V $127.12

(PM) CPM-4V $131.33

They don't list a market price for CPM-S110V -- you gotta call in for that one, which means it's volatile. Stuff's hard to make, I guess. And it's important to note that this is just the wholesale price for the material. Harder steels (the ones at the bottom of the list, S90V, 20CV, CruWear, M4, 3V and 4V) cost much more to grind and machine than the steels at the top as a general rule, so you need to figure that into the costs as well. But

My notes:

- If you expected more variation there, you are not alone.

- If you expected Cru-Wear to cost more, you are not alone.

- S35VN and S45VN are both cheaper than S30V, despite being marketed as improvements on S30V.

- 20CV costs less than twice the cost of 440C, but as a rule 20CV knives are going for a minimum of five times the price as 440C knives. Part of that's the additional machining and heat treating. Part of it.... isn't.

- And now you know why you see so much D2. (And that's just US made D2 -- the Chinese are known to sell several similar but still distinct steels as D2, all of which are even cheaper as they're often possessed of less vanadium than what is sold in the US as D2). And now you also know why even if it's US made steel, if it doesn't say CPM-D2, it isn't: $$$.

- If you're not really quite sure why there's so much daylight between 'budget' pricing, ($20-40) 'midtier' pricing ($40--120) and 'premium knife' pricing ($120 and up) for production knives, when the raw cost of the steels themselves are all within a single multiple of one another, understand that it's partially because of added expense and partially because knife companies know we'll pay.

(Edited)

reswright

3850

Jan 4, 2020

Spyderco Shaman, CPM-S30V/G-10 (oiled burlap Micarta scale rebuild)

reswright

3850

Dec 9, 2019

Doug Ritter RSK Mk1-G2, CPM-20CV/G-10

Doug Ritter is a knife designer and a big time knife rights advocate. He's the man behind KnifeRights -- a well known campaigner for the right to carry a pocket knife in America, which is another way to say his foundation is constantly at odds with state and city governments that pass restrictive and punitive knife laws. To fund his work he used to sell the Doug Ritter RSK, which was originally made for him by Benchmade and was extremely close to their standard Griptilian. A couple years ago Benchmade stopped producing RSKs for him under contract and wished him well and he ended up finding another home for the RSK at Hogue -- which was a company that started off making custom pistol grips, and by way of understanding things about handfeel and handle design, kind of ended up coming into the knife business via the back door. They're better known nowadays for making automatic knives with wild looking grippy handles, not graceful rounded handles like the Griptilian. But whatever deal Benchmade and Ritter parted terms with must have been fairly friendly, because the RSK Mk1-G2 that Hogue is making could still easily be taken for a Grip from a distance.

(Edited)

reswright

3850

Dec 7, 2019

GT-110 in ATS-34, aluminum alloy

So this one's kind of interesting.

(Edited)

reswright

3850

Dec 8, 2019

Seatrouteh, once I got it properly adjusted it was good to go. I don't know what they were thinking with a $250 sticker price, I'll give you that.

1Alexdropforged

18

Nov 25, 2019

There are probably a lot of fans of Columbia River Knife and Tool. I've so many crap knives from them that I simply won't ever buy another one.

reswright

3850

Nov 25, 2019

1AlexdropforgedIMO they don't count as an American knife company. They haven't made a production knife in the US for quite a while. If they were to start they'd have to subcontract the work out to someone else anyway.

I still do like some of their knives -- for example. if you have big hands, the Crawford/Kasper is a damn good knife for the cost. But I know where you're coming from. The truth is, I don't have a whole lot of time for CRKT as a company anymore. I think the tipping point was that time they took a Jesper Voxnaes design, gave it to Ken Onion, called it the Homefront and made it overseas outta AUS-8.

reswright

3850

Nov 11, 2019

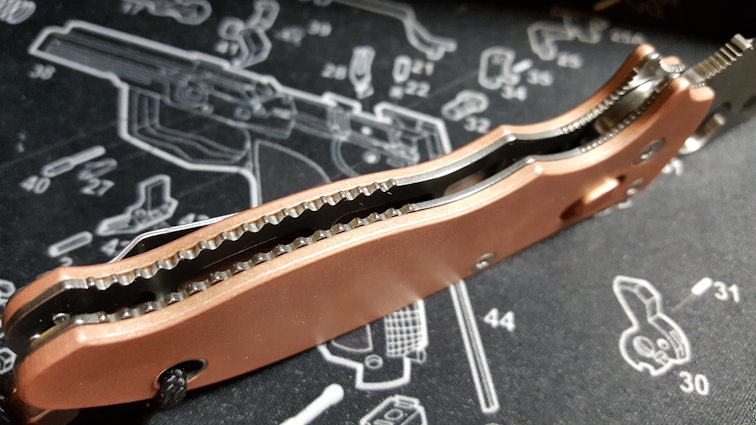

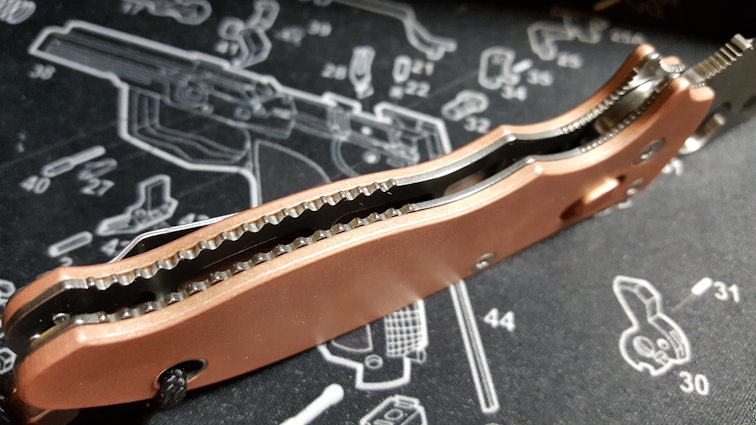

Spyderco Manix 2 Breakdown and Copper Rebuild

So I dig copper.

Not everyone does, for very respectable reasons. It's soft, so it scratches and nicks. It's heavy as sin, so any knife you put it on is going to be weighty. It changes its appearance over time. And to some folks copper smells faintly like bile.

But I'm a fan of copper in knives despite all these and even more reasons, because I like its luster.Copper knives were once a thing, both as copper ore and as bronze. It's old school and kinda pagan, which is probably why I like it.

So I picked up some aftermarket copper scales and a copper bearing cage for my new Manix, and resolved to give it a copper overhaul.

reswright

3850

Oct 24, 2019

Spyderco Manix 2 in Cru-Wear/G-10

reswright

3850

Oct 19, 2019

TOPS Street Scalpel 2.0 in 1095

KiefthePeace

5

Oct 2, 2019

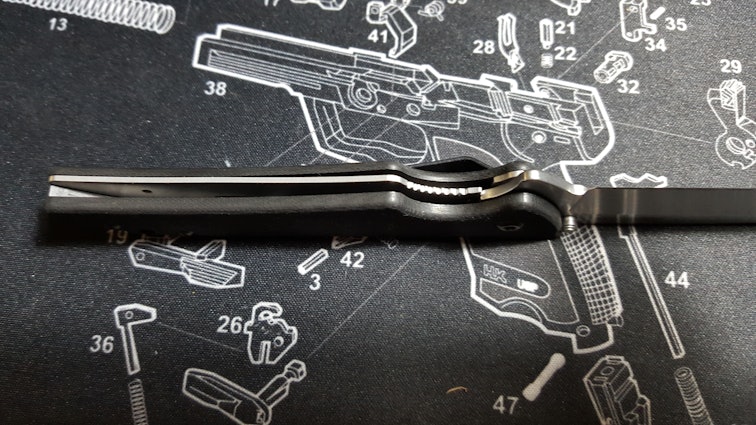

You need to give Zero Tolerance a call and tell them you need a low profile pocket clip for the "ZT0808" also known as the Kershaw launch 6 haha.

reswright

3850

Oct 1, 2019

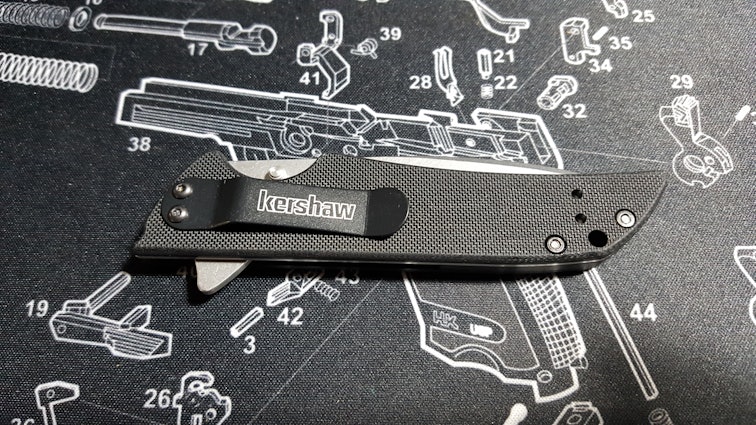

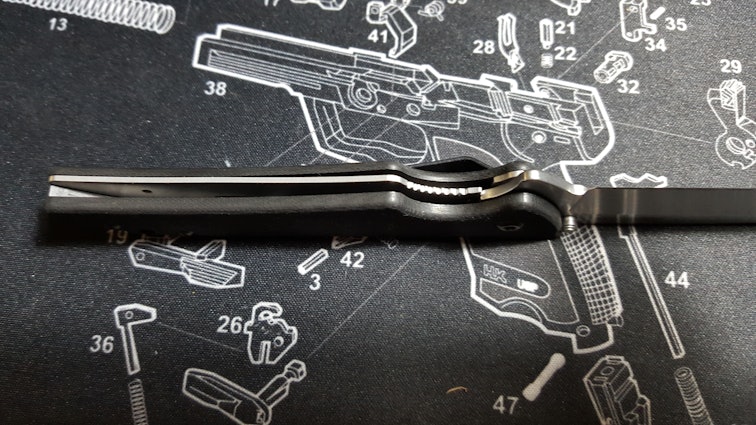

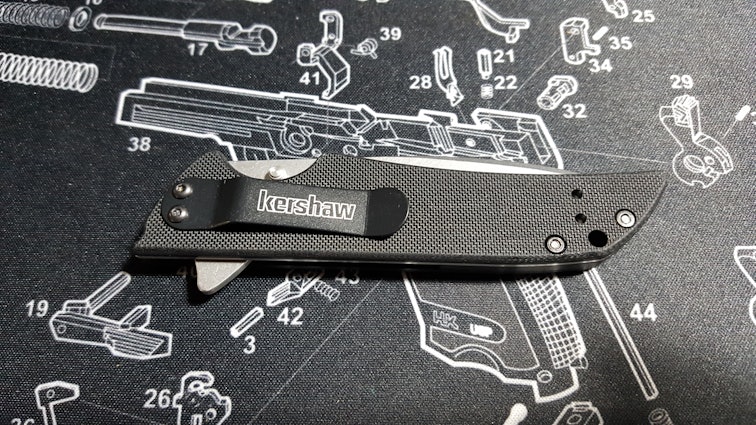

Kershaw 1760 Skyline, 14C28N/G-10

Showing 13 of 21

PRODUCTS YOU MAY LIKE

Trending Posts in More Community Picks

Graham88

Completely surprised by the lack of blade diversity here on Drop...

I’ve been a collector of Blades since before my teens, and a retailer coming up on 15… or maybe 20 years. Drop has really been kind of an interesting experience for me, because I do occasionally get to see some unusual tech and sometimes EDC items that otherwise I might not have been aware of. And maybe it’s because I have a deep love of cutlery and bladed weapons, but I find myself trolling through the site looking at it what’s available; and it’s just it’s pretty much the same. And the bladed community here is just always confused me.. every single knife is about the same, they’re almost all drop points and although the handle materials change and brands change.. it’s really just the same knife over and over and over again... occasionally you’ll see a tanto or a slight variant; but rarely… and almost never a serrated blade. And I’m just deeply amazed at this diversion of serrated blades. And I’m just surprised there isn’t more of a request for diversity here.... and I...

Mar 12, 2020

JellyDPhoto

Can we get Sony E-Mount or other mirrorless camera options please..

Would be nice to see some Sony E mount full frame cameras on here. I currently shoot with a A99 and they killed the lense path for better or more option lenses and now is all E-Mount. 🤔

Jan 13, 2020

RayF

There Are Pandas, and Then There Are Pandas.

And this isn't either of them! The Pandas we're talking about here, are watches, not bears. And what got me thinking about them (again) was a link posted this morning by @cm.rook who pointed a few of us to the very attractive (and not terribly priced) Yema "Rallygraph" Panda which, in it's most traditional arrangement, looks like the one on the left, but can also be had in the version on the right: The model on the left is a true Panda, while the model on the right is called a reverse Panda. The reason for that distinction is clear--Panda bears, only come in the first arrangement. Now at this point, everyone should be thinking about the most well-know Panda, The Rolex Panda, which is actually a Daytona, and among Rolex Daytonas, the most famous of which is the Paul Newman Daytona, which was famous first, because it was Paul's, and second because it sold at auction for $17.8 million (US Dollars). The story of that auction is well-known so I'll only...

Nov 8, 2019