Click to view our Accessibility Statement or contact us with accessibility-related questions

Showing 1 of 14 conversations about:

reswright

3850

Sep 16, 2019

bookmark_border

The lines are nice. I like the pivot collar, looks nice in the spare design.

Bohler Uddeholm M390 is often regarded as the first among equals when it comes to super steels -- although CPM-20CV and CTS-204P are just about impossible to tell apart chemically, and for that matter in any other way as well, M390 has a habit of turning out just a fraction of a hair better on some tests that are designed to simulate, like, years of wear. That may boil down to a slightly better PM technology producing a slightly purer and more even alloy matrix, or it might just be conventional wisdom at work and there's really no meaningful difference between the three steels. Whatever the difference, M390's good stuff.

Slip joints aren't really my thing, or I might pick one up. Spent too long pissing around with them as a kid to be all that nostalgic for them now, and once you get used to using locked blades, it's hard to go back. It's not a quality issue -- the truth is if people use them purposefully they're just fine, and they're less legally controlled and more socially acceptable than pulling out some bigass lockback, and a lot of people are making slipjoints again so clearly there's a demand. Just not from me.

anonomous

558

Sep 16, 2019

bookmark_border

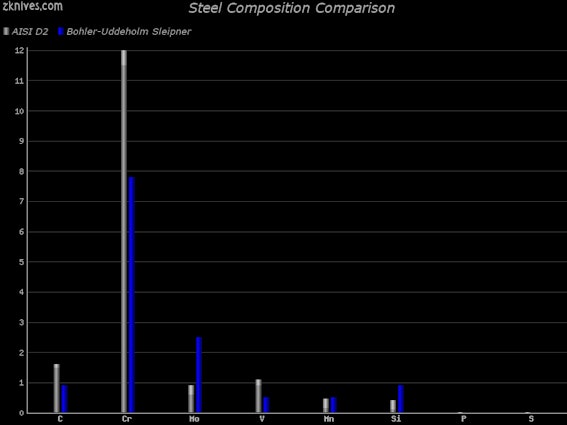

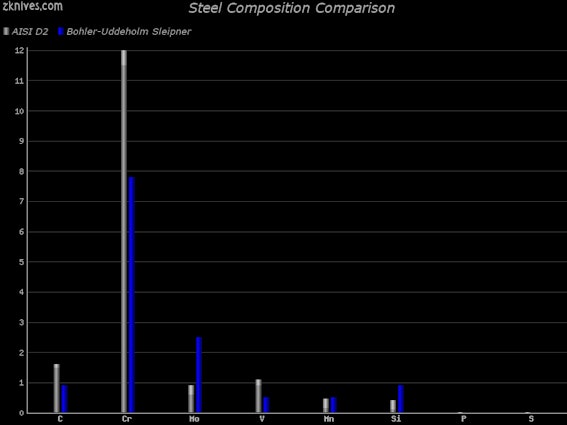

reswrightExcept it all varies on the heat treatment. And this class of steel is mostly done poorly. It is especially poorly done on the Italian knives where the focus is on corrosion resistance. So don't expect performance from fox, viper, mkm etc. In a test lionsteel did, m390 did 600 cuts and there sleipner did 1200. That's how bad they do this steel. Then 2nd parties have confirmed that the Italian m390 is a very poor performance steel due to there heat treatment process.

So value of these Italian brands is not good. They have nice looks but that is all.

But also most manufacturers of M390, 204p and 20cv struggle to also surpass s30v in edge retention. Because they want your money.

reswright

3850

Sep 16, 2019

bookmark_border

anonomousFair points. Heat and other treatments definitely matter, and Italian industry is better known for design than consistency. And we get so far into discussing the differences in individual steels that sometimes we forget that the average person can't even tell most of them apart, and the people who can, need some time to do so.

OTOH, Sleipner is kinda LionSteel's thing, so I'd also expect a little hype and inflation from them about it.

reswright

3850

Sep 17, 2019

bookmark_border

reswright

anonomous

558

Sep 17, 2019

bookmark_border

reswrighthttps://www.bladeforums.com/threads/lionsteel-steels.1168429/

It's cause they heat treatment the m390 for corrosion resistance and don't do a secondary hardening.

Check out the cut tests on the Italian m390 knives. It's pretty sad.

https://www.youtube.com/channel/UCI_ZXbN06A7W937hKKnUfqQ

Sleipner does pretty well in the tests that supersteel Steve did. So does elmax. There m390 could do alot better but because they burn the edges grinding them dry and do a sub optimal heat treatment it comes out just bad.

(Edited)

reswright

3850

Nov 15, 2019

bookmark_border

Aumank33...what Brad Zinker FR?

The comment's about a Lucas Burnley MKM slipjoint. At least, that's what I'm seeing. Says 'slip joint' all over the description and even mentions that it's got that 90/180 thing going on.

I have the certain idea that one of us is confused about something, but I'm not sure which of us it is.