Click to view our Accessibility Statement or contact us with accessibility-related questions

Cosmos Series 1u, 1.25u, 1.5u – Celestial Sphere artisan keycaps

search

close

Sort by: Newest

keyboard_arrow_down

Let’s get the conversation started!

Be the first to comment.

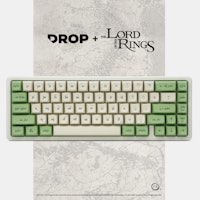

PRODUCTS YOU MAY LIKE

Trending Posts in Mechanical Keyboards

DaveKaretnyk

Mode Tempo with Red Samurai

Mode Tempo (60%) with GMK Red Samurai & Mode Lotus keycaps

Apr 25, 2024

dvorcol

Support for Alternative Layouts

This is a summary of how alternative layouts have been supported by kits such as Colevrak and Homing. It is not a discussion of alt layout performance and development, but if that interests you I highly recommend starting with Pascal Getreuer’s A guide to alt keyboard layouts (why, how, which one?). It’s a concise and comprehensive overview with links to some great sites that go deeper. He also has a separate Links about keyboards page. The Keyboard layouts doc he recommends explains layout goals and metrics in detail, summarizing the alt layouts discussed here as well as more than one hundred others. Sculpted-profile The majority of custom keycap sets are sculpted-profile (Cherry, SA, MT3, KAT, etc. - more on profiles generally here) so let’s start there. Because each row has a unique keycap shape, alt layouts require a unique keycap for each legend that moves off its QWERTY row. At first there were two The Dvorak layout was patented in 1936 by August Dvorak & William L....

Apr 23, 2024

CousinTimmy

Promo codes for stack Macropad v2

is there any promo codes right now that work with the STACK OVERFLOW THE KEY V2 MACROPAD? link:https://drop.com/buy/stack-overflow-the-key-v2-macropad?searchId=ead314359856d5486d35f4713cff32e9

Apr 23, 2024

Robbedoes

*Help* Screw in stabilizers not fitting in Dropshift V2 keyboard

I'm trying to build a mechanical keyboard with screw in stabilizers, I've build some mechanical keyboards with click-in stabilizers, never with screw in. Somehow one of the pins of the metal top-part collides with the screw in stabilizer of the numpad "enter key". I already tried grinding of a bit of the pin that collides with the stabilizer, but unfortunately I can't make it fit/close properly. You can see that the pin of the toppart leaves a mark on the bottompart of the stabilizer, see picture 2. What am I missing? Using Durock V2 in a Dropshift fullsize V2. See pictures below, thanks in advance!

Apr 23, 2024

Fukyachickennuggets

Polymer clay

Don't drop crazy cash on custom wood builds! Instead go buy polymer clay and paint. Then you can spend a ridiculous amount of time trying to make it look like you can afford to drop crazy cash on...

Apr 22, 2024

GrEEdYY

HELP PLEASE!

HELP PLEASE! I put noise insulation in the keyboard and after that it stopped working, the only sign of life is 5 blinks of orange light.can do something about it? model:DROP ALTv1

Apr 22, 2024

Now, fasten your seatbelt on the spaceship and together we will explore the planets. May we find magical elements we have been seeking! With the previous method of making Cosmo, the natural opal stones were used to represent the most realistic looks of the planets. And this time with Cosmo, let’s take a look at how we make this new keycap.

First, the glowing lines will be poured separately each mold to get a thin and sharp line, the lines will be completely dry and hard after 8-10 hours. The lines are luminously mixed so they can glow in the dark. With every stage of molding, the lines are being carefully cleaned to remove the excess resin to ensure sharpness.

Next, the planets are meticulously sculpted with lines on the surface of the clay, then we place it inside a mold and pour the resin, this step takes about 10-12 hours to finish. After the resin is completely dried, the resin ball will be cleaned off the excess resin and painted on the surface with other sculpted lines.

After a lot of steps as you can see, we have the completed details. The next step is fixed, this is a very important stage. With the lines in a keycap is a corresponding resin layer, fix the line in the right position and pour the resin then we wait for it to dry. ( This stage ensures no dust because the waiting time is equivalent to the time we pouring the lines )

Along with lines, positioning the planets are quite fascinating, the resin sphere is fixed with more resin layers to ensure the planets are located in the middle of the keycap.

At the final step, we need at least 16 hours for the keycap to completely dry. When the completed keycap is being removed from the mold, cleaning and cutting off the excess resin must be done carefully.

To make the keycap surface looks glossy and smooth, the rough finishing keycap needs to rest for 8-10 hours and sanding is performed from 1-5 respectively with different sandpaper levels from 240-2000.

The finished Cosmo is being checked again, clean the entire keycap, paste the serial number and place in the wooden box. Waiting for delivery to your house.