Click to view our Accessibility Statement or contact us with accessibility-related questions

Battlestations

storyboardtech

417

Nov 9, 2023

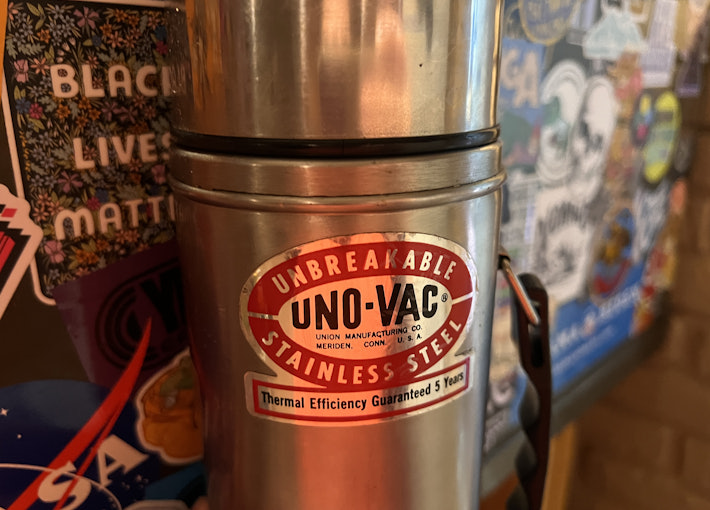

Balancing act: crafting authentic deskscapes

My grandpa was a truck driver for 40 years, and in that time he used two thermoses. I own them both, and the smaller of the two, which was clearly used on hundreds of runs, has a scratched and faded line of text below the label that reads “Thermal Efficiency guaranteed 5 years.” It might as well have said “105 years” because it works as well today as the day he bought it. That thermos is incredibly well designed, well made, and I assume it will work for another 50 years unless something drastic happens to it.

You’ll often hear people say “they don’t make things like they used to” and in my experience, that’s largely true. Products in the past were often made with longevity in mind, and to be honest, it was easier to build them so sturdy back then. Tools weren’t computerized, the parts weren’t as tiny, and the types of metal and plastic they were made from were costly and often machined with a human involved in the process.

I adore technology and surround my desktop space...