Click to view our Accessibility Statement or contact us with accessibility-related questions

Showing 1 of 998 conversations about:

Drop + OLKB Preonic Keyboard MX Kit V3

SiL3nTOne

5

Mar 2, 2018

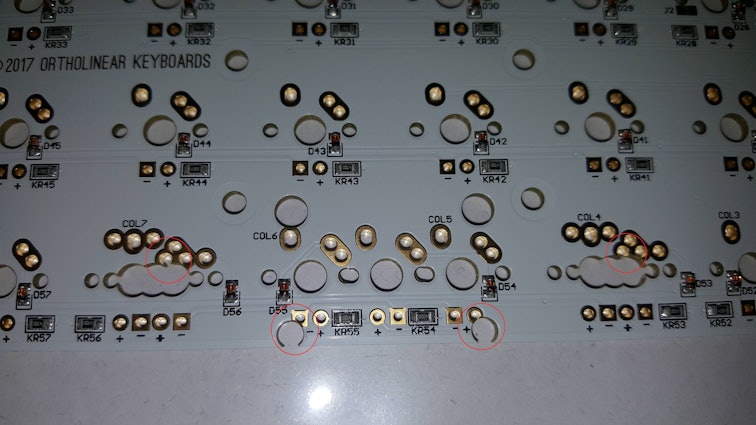

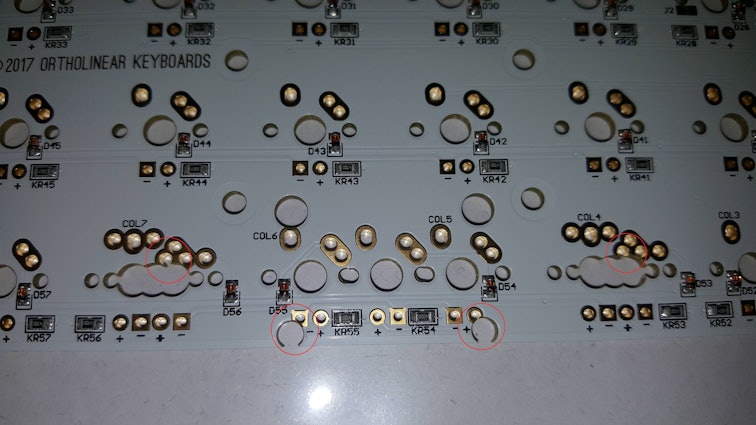

How does this pass for Quality Control? Solder points are blown out from when they drilled the other holes in the PCB.

Flyingpike

38

Mar 2, 2018

SiL3nTOneMaybe I am missing the issue, but my board looks like this, as does a Duck Lightsaver pcb that I am currently using with no issues. I think these "blow outs" are pretty common for boards that support multiple layouts and shouldn't affect your ability to insert and solder switches and LEDs.

SiL3nTOne

5

Mar 2, 2018

FlyingpikeFor the amount of money and the wait time this is not the level of quality that i expected, i'm not worried about crescent moon shaped holes in the bottom of the board. What i am worried about and would not risk is soldering in a crescent moon shaped solder hole and pad that is clearly not supposed to be that way.

Flyingpike

38

Mar 2, 2018

SiL3nTOneThey’re supposed to be that way. The images on the description for this drop show them this way. If you look at any plank or preonic build log and you can see the pcbs have holes and pads just like yours. As do almost every other custom keyboard pcbs that support multiple bottom row layouts. I don’t think you need to be worried about any soldering issues. If you are using the standard layout I don’t think you’ll even be using the crescent shaped holes except for LEDs maybe. It isnt a quality issue, it’s by design.

jackhumbert

1040

OLKB

Mar 8, 2018

SiL3nTOneThose are by design (and have always existed in our designs) - the lower ones are for the PCB-mounted stabiliser, and they don't affect the ability to solder onto the points. The others are for over switch positions (1.25u and 1.5u keys). Overlapping footprints like this are necessary to pack-in all of the features we'd like :)

PRODUCTS YOU MAY LIKE

Trending Posts in Mechanical Keyboards

NewmanDA9901

LOTR Keyboard with Hardcore keycaps?

Hello. Is there a way to get the DROP + THE LORD OF THE RINGS™ BLACK SPEECH KEYBOARD with only the HARDCORE BASE KIT keys? Without the English letters on it. I really want one but it would be awesome if it came with the hardcore kit installed. Thanks in advance!

May 2, 2024

mabyen

Battlestations

Black Speech keyboard

Looks and feels good and mechanical sound is great!

May 1, 2024

dovenyi

What is SpaceFN and why you should give it a try

The SpaceFN concept - setting up your space key as a layer switch when held - is probably one of the most useful tweaks in the keyboard hobby. Let me explain how it works. My SpaceFN article on kbd.news made some rounds recently - quite surprisingly given the age of this concept. This piece you're reading is a condensed version of the full post. If you're left with unanswered questions, you'll most likely find the info you're looking for in the original write-up. On my imaginary top list of the most useful keyboard features, tweaks and hacks, SpaceFN would deserve a podium finish for sure. But what makes it so special? In short: SpaceFN is easy to implement, easy to learn, costs nothing, can be used with any keyboard, and can improve your productivity instantly. I will list its benefits below, but can state right at this point that the SpaceFN concept, setting up your space key as a layer switch when held, is clearly one of the most useful tweaks in the keyboard hobby....

Apr 30, 2024

Ike4948

Silent Holy Panda X?

I ordered some Holy Panda X switches, and I fell in love with them. They are a joy to type on. There's just one problem. The place that I use my keyboard to type the most is obviously at work, which is a problem if I want to use the Holy Panda X in the office around a whole bunch of people. I really don't want to torture my coworkers with the clack of these switches. I'd rather they still liked me. The good news is that, for me, the actuation of the Holy Panda X is the best part. I could take or leave the sound it makes; even if it is fantastic. Which leads me to my conundrum: is there another "silent" switch that feels similar to the Holy Panda X? Is there a piece I can remove from the Holy Panda X that would allow me to make them silent? Or am I going to have to wait and see if Drop will drop a Silent Holy Panda X for the in-office mech community?

Apr 29, 2024

DaveKaretnyk

Mode Tempo with Red Samurai

Mode Tempo (60%) with GMK Red Samurai & Mode Lotus keycaps

Apr 25, 2024