Drop + Degnan Emrose Folding Knife

Slim, Savvy & Street Smart

The stiletto is one of the most iconic blades in history. Originally a needle-pointed weapon from 15th-century Italy, then a quintessential sidearm for rebellious gangsters (especially on the silver screen), it’s made an indelible mark on our culture. So, it should come as no surprise we wanted to make a version of our own. A collaboration with knifemaker Matt Degnan, the Emrose sports a slim profile, contoured handle scales, and a nimble blade with fast, snappy action. Weighing a mere 2.2 ounces and measuring just a half-inch thick, this speedy flipper conceals easily, yet rises to the challenge when needed. Backed by a titanium frame lock, the 3.2-inch blade is made from premium S35VN steel for an edge that’ll hold through thick and thin.

Note: Due to the sensitive nature of shipping knives internationally, we can only ship this knife to select countries. It is the responsibility of the buyer to know and comply with all importation regulations and local laws. Click here for additional information.

Engineered for Precision

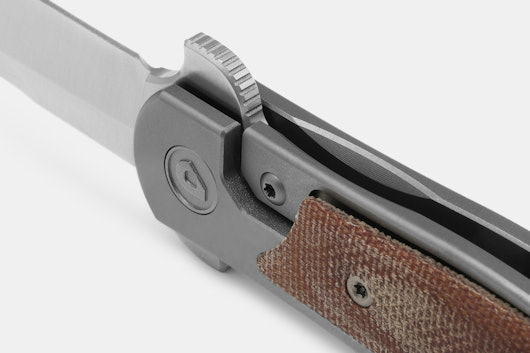

Thanks to its slim frame and slender blade, the Emrose can navigate in tight spaces with ease. The flipper tab has strategic jimping for a solid grip. Once deployed, the flipper acts as a finger guard to prevent your fingers from sliding up into the blade’s edge. There’s also a hardened steel lockbar insert and an over-travel stop tab to preserve the life of the lock. As for the handle, it’s made primarily of 6AL4V titanium, with contoured inserts in micarta or carbon fiber. Whatever model you choose, the backspacer will be a perfect match to the inserts for a cohesive look. While the Emrose looks great without a clip, we’ve included one milled from titanium for tip-up carry on the right side.

A Closer Look at S35VN

Developed by Crucible Industries (one of the leading manufacturers of specialty steels for the cutlery industry) and Chris Reeve (pioneer of the integral frame lock), S35VN is perhaps the most balanced blade steel ever created in terms of all-around performance. It’s made through a process known as Crucible Powdered Metallurgy, which results in near-perfect consistency in the distribution of carbides. Compared to conventional melting practices, the CPM process produces a steel characterized by superior dimensional stability, grindability, and toughness.

Matt Degnan Knives: Practice Makes Perfect

Like many other knifemakers, Matt Degnan’s love for knives took hold as a young boy. At age 8, the day his father gifted him a bone-handled Case knife on a fishing trip—a smaller version of the one dad carried in his tackle box—Degnan was hooked. Twenty five years later, Degnan discovered the world of custom knives on Instagram. Inspired by other makers’ work, he tried designing one of his own. The first few were rough, but plenty of practice and research on Usual Suspect Network turned his work around fast. Today, Degnan boasts a handful of successful designs under his belt and continues to innovate with a style all his own.

About WE Knife

Since its founding in 2000, WE Knife has set a new standard for manufacturing in China. With a professional research and development team, high-quality facilities, and a commitment to precision manufacturing techniques, the company produces a wide range of cutlery manufactured to the highest tolerances.

Model Options

Bead Blasted – Natural Brown Micarta

Bead Blasted – Natural Brown Micarta Gold – Coral Red Micarta

Gold – Coral Red Micarta Stonewashed – OD Green Micarta

Stonewashed – OD Green Micarta Black – Carbon Fiber (+$15)

Black – Carbon Fiber (+$15) Blue – Carbon Fiber (+$15)

Blue – Carbon Fiber (+$15) Purple – Carbon Fiber (+$15)

Purple – Carbon Fiber (+$15)

Specs

- Designed by Matt Degnan

- Manufactured by WE Knife

- Made in: Yangjiang, China

- Blade: S35VN stainless steel

- Blade profile: Spear

- Blade grind: Flat with swedge

- Blade finish: Satin

- Handle: Titanium frame with micarta or carbon fiber scales and backspacer

- Handle finish: Varies

- Open mechanism: Flipper tab

- Lock: Frame lock

- Pivot: Caged ceramic bearings, hardened steel washer

- Pocket clip: Milled titanium

- Hardware: Titanium, Torx T6, T8

- Blade length: 3.2 in (8.2 cm)

- Handle length: 4.1 in (10.5 cm)

- Overall length: 7.4 in (18.8 cm)

- Blade thickness: 0.12 in (3 mm)

- Handle width: 0.5 in (1.2 cm)

- Overall weight: 2.2 oz (63 g)

Included

- Zipper pouch

- Cleaning cloth

- Drop 1-year warranty

Image Disclaimer

Images are of a product in the prototype stage. The final product may differ slightly.

RETURNS—NO QUESTIONS ASKED

We get it. Sometimes what you ordered just doesn’t work out. If that’s the case for you, don’t fret! All customers (both US and international) may return this item in new, unused condition within 30 days of delivery.

Shipping

Estimated ship date is May 25, 2021 PT.

Payment will be collected at checkout. Cancellations are accepted up to 2 hours after checkout for in-stock items, or up until pre-order ships.