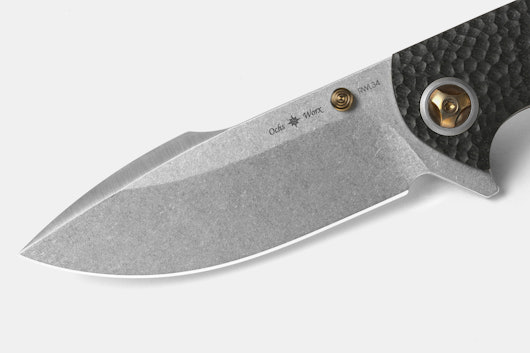

Massdrop x Eric Ochs Orca Titanium Liner Lock Knife

A Dependable Folder With Signature Ochs Styling

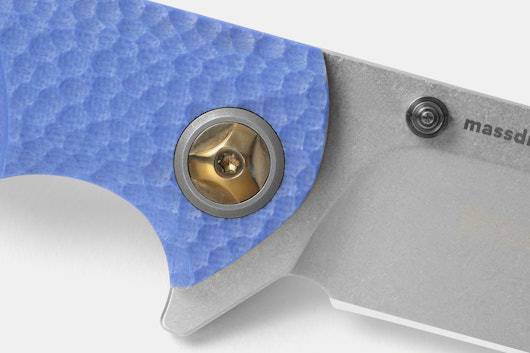

If anyone understands the importance of a good knife, it’s Eric Ochs. Growing up in the Oregon countryside, Ochs naturally gravitated toward knives for outdoor pursuits, and in the mid-2000s he made his first one. The Orca is based on the custom design that put him on the map. A full-sized folder with a 3.5-inch harpoon-style blade, it’s equally suited to piercing, slicing, shaving, and more. The knife is full of elements you’ll find throughout Ochs’ work: There’s a raised martle swedge on the blade (a detail that’s influenced the knife industry as a whole), a curved titanium pocket clip that matches the contours of the handle, and matching anodized titanium liners and hardware. The blade is made from RWL34 stainless steel, which boasts good edge retention, toughness, and corrosion resistance. Diagonally separated with a smooth texture on the bottom half and a stippled texture on the top half, the handle is available in your choice of six different styles.

Note: Due to the sensitive nature of shipping knives internationally, we can only ship this knife to select countries. It is the responsibility of the buyer to know and comply with all importation regulations and local laws. Click here for additional information.

Smooth to Deploy, Comfy to Carry

Looking at the Orca from the side, it bears a certain resemblance to the whale it’s named after. The base of the handle slopes downward, similar to the way the whale’s body slopes downward toward the tail. Here, that makes the handle super comfortable for both a standard and reverse grip. If that wasn’t enough, the dimpled texture and raised backspacer offer even more security when things get slippery. Opening the knife is easy, too. This can be achieved two different ways: You can press the flipper tab or rotate the blade by way of the thumbstuds. Either way, the caged bearing system provides effortless deployment. Once open, the flipper tab makes an excellent guard to protect your fingers. For carry, the knife is fitted with a milled titanium pocket clip for right-handed, tip-up carry.

A Closer Look at RWL34 Stainless Steel

RWL34 is named after iconic knifemaker Bob Loveless, who popularized the hollow-ground drop-point blade and the use of full-tapered tangs and screw-type handle scale fasteners. Loveless originally employed ATS34 ball-bearing steel to meet the demands of his custom knives, but knew it could be improved further. Similar to ATS34, but made through Damasteel's state-of-the-art Rapid Solidified Powder process, RWL34 is a tribute to Loveless’s legend. It performs best at high hardness, takes a wicked sharp edge, and can be sharpened with relative ease—all while maintaining excellent toughness and strength.

The Eric Ochs Philosophy

“If you don’t have a good handle, you don’t have a good knife. If you can't hold on to a knife, you can't cut very well." Growing up in Oregon against a backdrop of rivers, valleys, and forests, Eric Ochs understood this from an early age. In fact, that age was six, when his father gave him his first pocket knife. A year later, Ochs got his first Swiss Army Knife, and today he can’t remember a day without a folder by his side. A self-taught talent, Eric started making knives in 2007. His designs have become known for their blend of simplicity, balance, and function. He’s also an avid hunter, fisherman, and kayaker, so he has ample opportunity to field test his knives—which is testament to why they’re so useful for a wide range of tasks.

Reate: A Story of Precision Craftsmanship

A small and highly respected original equipment manufacturer in China, Reate was founded in 2012 by David Deng, a longtime knife enthusiast with a background in mechanical design and manufacturing. Since starting the business, Deng has expanded its capabilities to offer key services like wire EDM precision cutting, laser engraving, CNC milling, low-temperature tempering, custom hand finishing, and more. Owing to the company’s impressive work, Reate has earned the opportunity to work with knifemakers around the world, including names like Liong Mah, Tashi Bharucha, David Mosier, and Todd Begg.

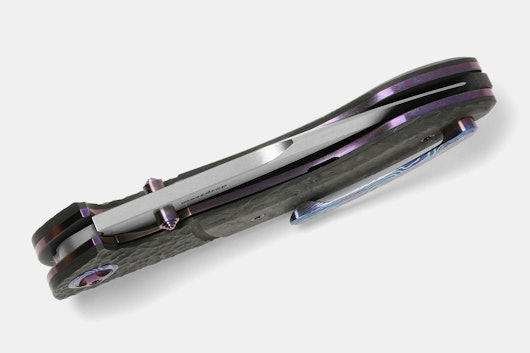

Carbon Fiber Upgrade Models

If you're looking for a real statement piece, go for an upgraded version with carbon fiber and blue or purple Moku-Ti hardware. Featuring marbled carbon fiber scales and a matching backspacer, these are lighter and just as strong as the G-10 versions. To make them really pop, the clip and pivot collar are made from Moku-Ti: a multi-layer titanium alloy that is forged by hand in Mississippi at Nichols Damascus, then carefully heat treated, resulting in a swirled mosaic of blue and orange or silver tones. Of course, because of the materials used in these upgraded versions, they're limited to just 400 units total.

Style Options

Black G-10 – Bronze Titanium

Black G-10 – Bronze Titanium Blue G-10 – Bronze Titanium

Blue G-10 – Bronze Titanium Green G-10 – Bronze Titanium

Green G-10 – Bronze Titanium Marbled Carbon – Blue Mokuti (+$125)

Marbled Carbon – Blue Mokuti (+$125) Marbled Carbon – Purple Mokuti (+$125)

Marbled Carbon – Purple Mokuti (+$125)

Specs

G-10 Models

- Designed by Eric Ochs

- Produced by Massdrop

- Manufactured by Reate

- Country of Origin: China

- Blade steel: RWL34 stainless steel

- Blade profile: Harpoon (drop-point)

- Grind: Flat saber

- Finish: Stonewashed with satin swedge

- Handle: G-10

- Handle: Stippled bolster area

- Opening mechanism: Flipper tab

- Lock: Titanium liner lock

- Pivot: Caged bearings

- Right-handed tip-up pocket clip: Titanium

- Lanyard hole

- Hardware: Torx

- Blade length: 3.5 in (8.9 cm)

- Blade thickness (at spine): 0.16 in (4.1 mm)

- Blade thickness (at edge of grind/bevel): 0.02 in (0.6 mm)

- Handle length: 4.5 in (11.5 cm)

- Handle width: 0.6 in (1.5 cm)

- Overall length: 8 in (20.4 cm)

- Weight: 4.75 oz (135 g)

Carbon Fiber Versions

- Handle: Carbon fiber

- Carbon fiber backspacer

- Right-handed MokuTi pocket clip

- Satin-finished blade

- Weight: 4.4 oz (125 g)

Included

- Warranty

- Pouch

- Microfiber cloth

RETURNS—NO QUESTIONS ASKED

We get it. Sometimes what you ordered just doesn’t work out. If that’s the case for you, don’t fret! All customers (both US and international) may return this item in new, unused condition within 30 days of delivery.

Shipping

Estimated ship date is Mar 22, 2021 PT.

Payment will be collected at checkout. Cancellations are accepted up to 2 hours after checkout for in-stock items, or up until pre-order ships.